Chromium Carbide Overlay (CCO) Plate Wires

WearEx® H2000-S

WearEx H2000-S wire (1/8'' or 7/64'') is a self-shielded flux cored hardfacing chromium carbide overlay (CCO) wire specifically designed for single-layer CCO plate welding using an open-arc process.

WearEx® H2000-M

WearEx H2000-M wire (1/8'' or 7/64'') is a self-shielded flux cored hardfacing chromium carbide overlay (CCO) wire specifically designed for multi-layer CCO plate welding using an open-arc process.

Available in drum or spool

550 lbs/drum or 55 lbs/spool

Complex Carbide Plate Wire

WearEx® H3000-S

WearEx H3000-S wire is a self-shielded flux cored hardfacing complex carbide overlay wire specifically designed for single-layer complex carbide plate welding using an open-arc process.

WearEx® H3000-M

WearEx H3000-M wire is a self-shielded flux cored hardfacing complex carbide overlay wire specifically designed for multi-layer com plex carbide plate welding using an open-arc process.

Available in drum or spool

550 lbs/drum or 55 lbs/spool

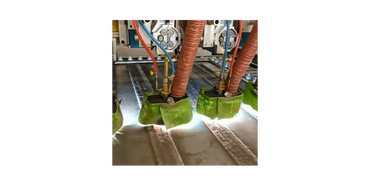

Behind the Scenes of WearEx's Quality Control

From Raw Materials to Finished Products: A Journey with WearEx's Hardfacing Plate Wires

WearEx® plate wires are packed in drum.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.